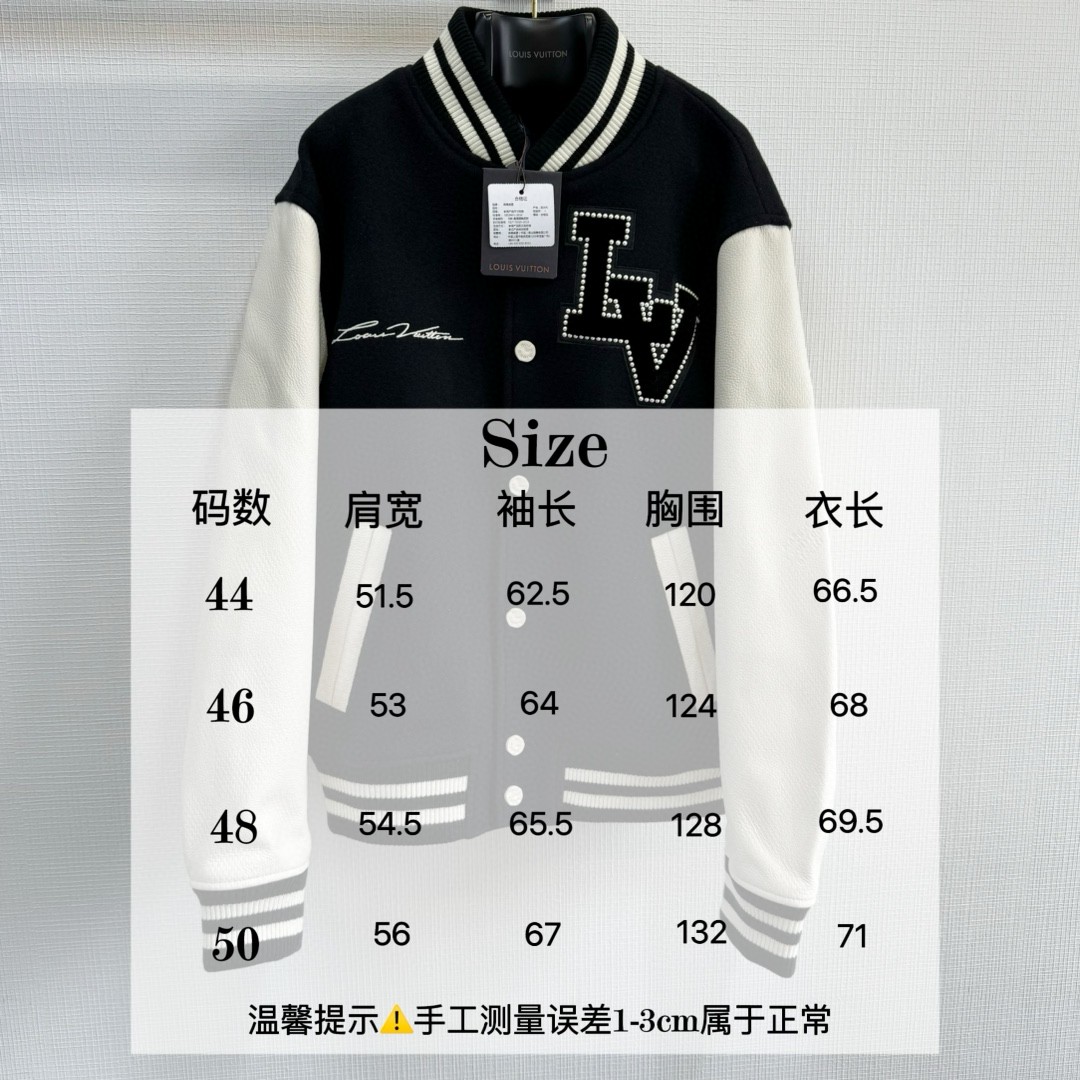

1vvv x Pharrell 24ss checkerboard embossed leather baseball jersey

Official website price: 51000¥

The fabric is made of 80% wool, weighing 750g, with a newly cut wool embryo bottom and dyed with reactive black in the tank,

The fabric is made using the “Stirring Technique” and undergoes 5 rounds of brushing and 6 rounds of washing. After that, the fluffy surface fluff is trimmed flat, presenting a “hollow three-dimensional fluffy effect” on the surface of the fabric. The elasticity of the fabric can be felt by touching and pressing it with your hand. The newly cut wool yarn is in the form of long fibers, and after shearing, it is not easy to pill. The front and back panels are embroidered using the “Japanese imported Tajima Embroidery Machine”, and the nylon material is super matte. The tatami needle method is used for multi-layer layered embroidery. The front panel is embroidered with “adhesive material yarn” and “three-dimensional toothbrush embroidery”. In the later stage, the fluff height is manually flattened by opening the mold and using “acrylic material circular foam beads”, and the foam bead surface is made. Triple spray painting process: The primer uses latex paint as the base material, the middle layer is sprayed with pearl white paint, and the outer layer is sprayed with translucent bright topcoat, The translucent and bright white effect is completely comparable to mother of pearl shells. Zhangzi has a total of 154 round beads, each of which is scanned and positioned to ensure that they are level at the edge of Zhangzi, and the visual effect is not abrupt. The two sleeves are made of water dyed cowhide, which has no attached objects on the surface compared to spray painted cowhide. The pure water-based dye tank is constantly stirred and naturally colored. During the process, samples are taken to compare the color of the Y-shaped sleeves according to the degree of coloring. When the color is basically the same, the finished product can be washed with water and naturally dried. The finished leather material is made of 12mm thickness, embossed with a large size of aviation aluminum plate material mold, and all are sorted and pressed according to the positioning pattern. The electric oil pressure control system is used, and the constant temperature and timing are used. Automated operation, the sleeve small logo small mold is individually embossed and pressed using electromagnetic pulse pressure heating, After the sleeve cutting is finished and embossed, all the leather bottom is scraped according to the thickness of 8mm. The thickness of the leather material is reduced, and the hand feel becomes soft and close fitting. The surface diamond grid pattern is embossed due to the thinning of the leather bottom, resulting in a reverse skin phenomenon. The pattern will naturally rise and become lighter from the deep bottom state. The diamond grid pattern and the lychee pattern of the leather material form a visual hidden effect. It is matched with a copper ammonia silk+cotton blended lining fabric, and the ribbed pattern is made of combed cotton yarn. The cross woven weaving machine imported from Taiwan has a color jacquard pattern, and it is matched with a customized aluminum alloy material with logo spray bright finish and four in one buckle.

BAGS

BAGS CLOTHES

CLOTHES SHOES

SHOES WATCHES

WATCHES

评价

目前还没有评价